Blog

Application Field: Secondary Mullite Formation for Refractories and Ceramics

Explore an emerging application for kyanite

Application Field: Shrinkage Control for Refractories and Ceramics

The #1 Use of Kyanite Worldwide

Our Culture: A Chat with HR Manager, Casey Diamond

Take a deeper dive into our company culture…

Kyanite Fall Newsletter

Back to school, environmental stewardship, holiday card design contest & more!

Our Environmental Stewardship: Prevention

Preventing air, water and solid waste pollution.

Our Environmental Stewardship: Reclamation

At Kyanite Mining Corporation, we take immense pride in our industry-leading approach to environmental stewardship, from our resource management practices to our award-winning reclamation efforts.

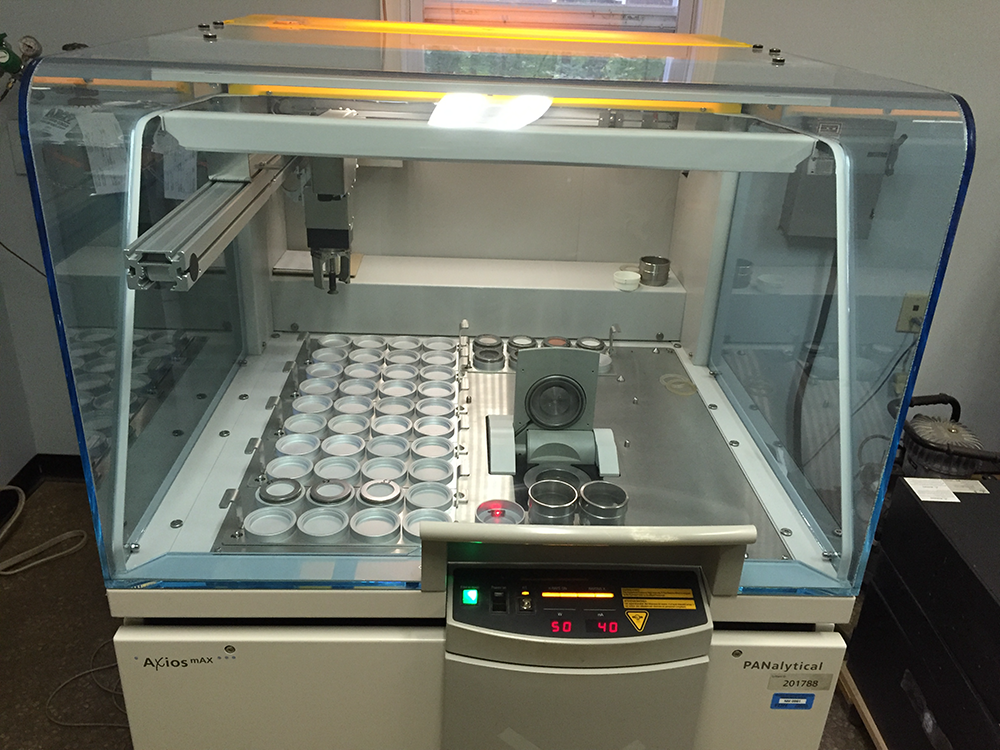

Quality Control

Quality Control is the cornerstone of our operations here at Kyanite Mining Company.

How It’s Made / PART 3: Milling, Sizing, and Bagging

And now, we wrap up with milling, sizing, and bagging our Virginia Kyanite for worldwide distribution.

How It’s Made / PART 2: Removing Impurities

In this second installment, we’ll cover the meticulous process of removing clay, soil, pyrite, quartz, mica, iron oxides, and other impurities from the mined ore

How It’s Made / PART 1: The Deposit and Mining

In this first installment, we shed light on our source mines at Willis Mountain and East Ridge in Dillwyn, Virginia, and the process of mining these world-class ore bodies